Improve grinding efficiency and reduce production cost

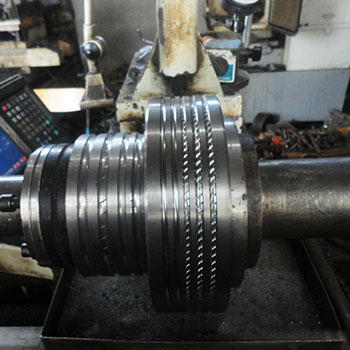

Roll belongs to large parts, usually high hardness, difficult to process.For high hardness and difficult to process roll, such as rebar steel roll, wire roll, plate roll, vic tool can provide a perfect solution - different materials of CBN tool to meet the needs of processing conditions.

Common roll materials are: high-speed steel roll, carbide roll ring, alloy cast iron roll, repair roll, surfacing roll, cold hard cast iron roll. ztsuperhard will provide suitable CBN inserts grades for different materials.

Solid CBN inserts for cast iron roll

RNGN Solid CBN inserts

RCGV Solid CBN inserts

SNGN Solid CBN inserts

Processing material: high ni-cr cast iron, chilled cast iron, etc

Processing process: rough, semi-fine

Advantages: Zt for cast iron roller processing development of solid cbn inserts, has excellent impact resistance, high wear resistance, to ensure the workpiece processing accuracy while extending the tool life, improve the processing efficiency.

Solid CBN inserts for hhs roll

RNGN Solid CBN inserts

RCGV Solid CBN inserts

SNGN Solid CBN inserts

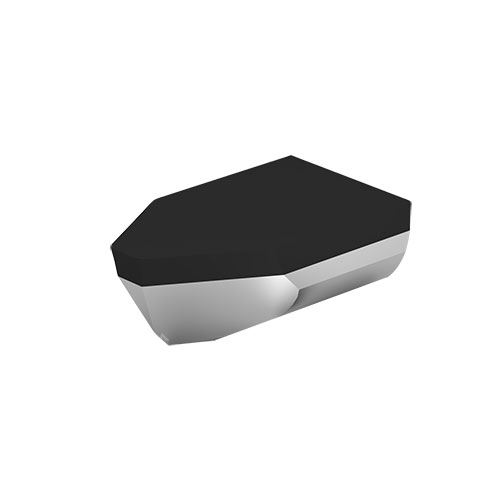

PCD inserts for carbide roll

Processing material: forged steel, HHS, carbide

Processing process: rough, semi-fine

Advantages: Zt solid cbn inserts processing high hardness steel roll, compared with traditional tool efficiency.

Processing parts: groove cutting, outer circle, end face

Processing process: groove processing, finishing processing

Working condition: dry cutting

Advantages: zt slotting inserts prolongs tool life, supporting tool bar, and improves processing efficiency.

Cubic boron nitride cbn tool cutting roller process can be large margin cutting and intermittent cutting, and can process high hardness material roll, For more information, please contact Alice, email: sales@ztsuperhard.com, mobile: +86 17329325308