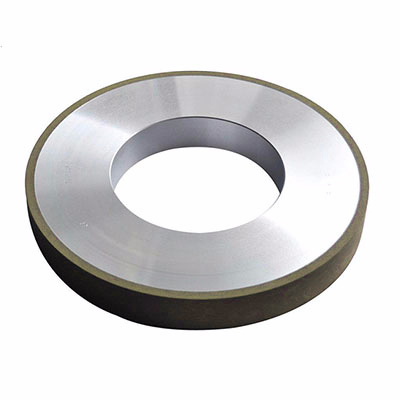

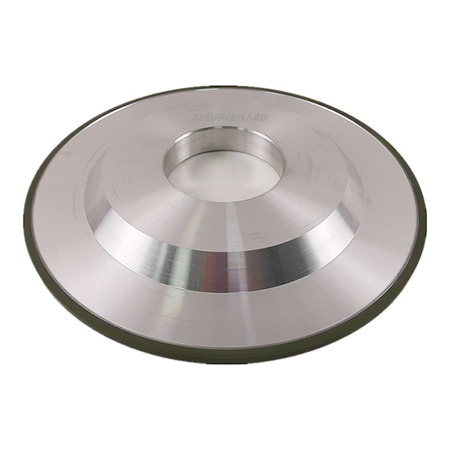

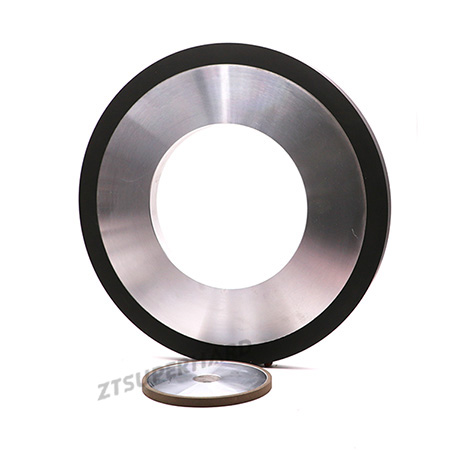

Diamond grinding wheel of proper grit should be used for grinding tungsten carbide dies. Green grit wheels should be avoided because they present too many hazards to the die. An ideal combination of wheels for grinding carbide would consist of a 100-grit wheel for roughing and a 180-grit for finishing. However, the use of a 150-grit wheel for both roughing and finishing is practical. Whether the combination of wheels or the all-purpose wheel is used, all wheels should have the same general specifications other than grit size. These would include a diamond concentration of 100 and bonding hardness.Peripheral speed of grinding wheel should be approximately 4200 surface feet per minute (sfpm)(1260 surface meters per minute - smpm) with table speeds of approximately 85fpm(25.5mpm) for roughing cuts. Speed should be increased above 85fpm for finishing. Cross-feeds of 0.25 inch to 2.7 inch (6.3mm to 69mm) are correct for roughing cuts. For finishing cuts the cross-feed should be reduced to 0.03inch (0.8mm).

Whichever method is used for die sharpening, it is necessary that punch exposure be kept a minimum. The brittleness of carbide makes it an almost delicate material.